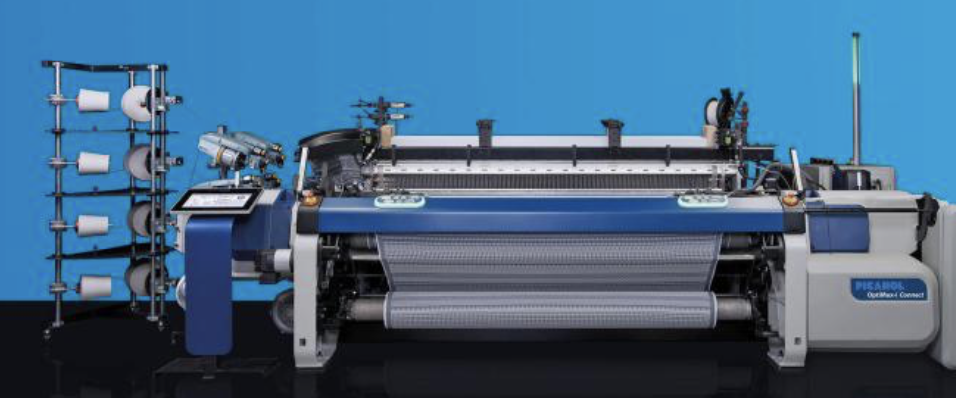

Our World-Class Infrastructure

Empowering Quality Manufacturing with Precision and Expertise

Where Innovation Meets Manufacturing Excellence

At Tulah, our infrastructure is the backbone of our ability to meet and exceed client expectations. With a 10-year legacy of excellence, we bring together advanced technology, sustainable practices, and a team of skilled professionals to craft high-quality textiles. From yarn dyeing to packaging, every step of our production process is optimized for efficiency, quality, and sustainability.

Our cutting-edge facilities and deep industry expertise enable us to deliver premium textile solutions. At Tulah, we believe that exceptional products are crafted with the support of superior infrastructure.

Key Facilities

Our infrastructure is built to handle the demands of modern textile production, ensuring precision, consistency, and scalability.

Built to Deliver at Scale

With a robust daily production capacity of 4 tonnes (minimum 3.5 tonnes) and a proven monthly output of 100 tonnes (based on recent performance), our infrastructure is designed to handle large-scale orders with unmatched efficiency.

Advanced Technology

Our factory is equipped with advanced machinery and processes that ensure superior quality and efficiency:

- Energy-Efficient Machinery: Optimized for lower energy consumption while maintaining high output.

- Sustainability-Driven Practices: Incorporating RO-treated water and exploring infrared dyeing technologies.

- Commitment to Innovation: Future plans include adopting supercritical CO₂ dyeing and expanding into PLA fiber processing for eco-friendly solutions.

Committed to a Greener Future

At Tulah, sustainability isn’t just a buzzword; it’s our mission.

- We utilize advanced RO water treatment to recycle and reuse water in our dyeing processes.

- By minimizing chemical waste and optimizing energy usage, we actively reduce our environmental impact.

- Our vision includes adopting cutting-edge technologies like supercritical CO₂ dyeing to eliminate water and effluent use altogether.